Quality

Quality Policy

-

Intelligent innovation

-

Lean manufacturing

-

Create value for customers

-

Intelligent innovation

Take Lean Design as the Guide to Promote Platformization, Lightweighting and Standardization of Products

Optimize the products: realize the functions of the products with least number of parts, processes, steps, turnovers and procedures

Continue to innovate forever -

Lean manufacturing

The design error-proofing, equipment error-proofing, tooling error-proofing to ensure product quality, automatic and on-time production to realize intelligent manufacturing

Continuously improve product quality to reduce costs and increase efficiency -

Create value for customers

Create value for customers with optimal solutions, fast delivery and timely and effective service

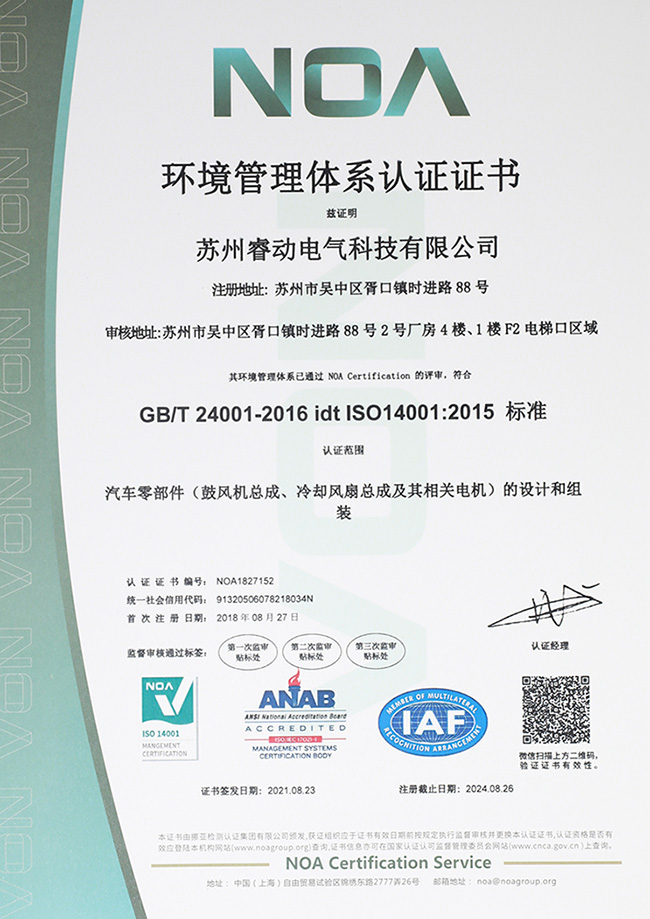

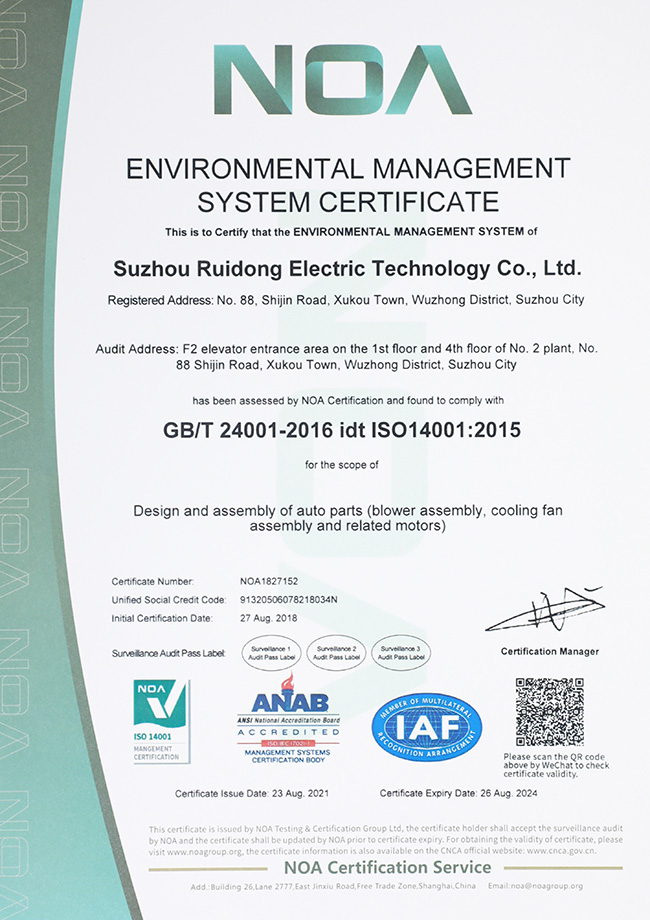

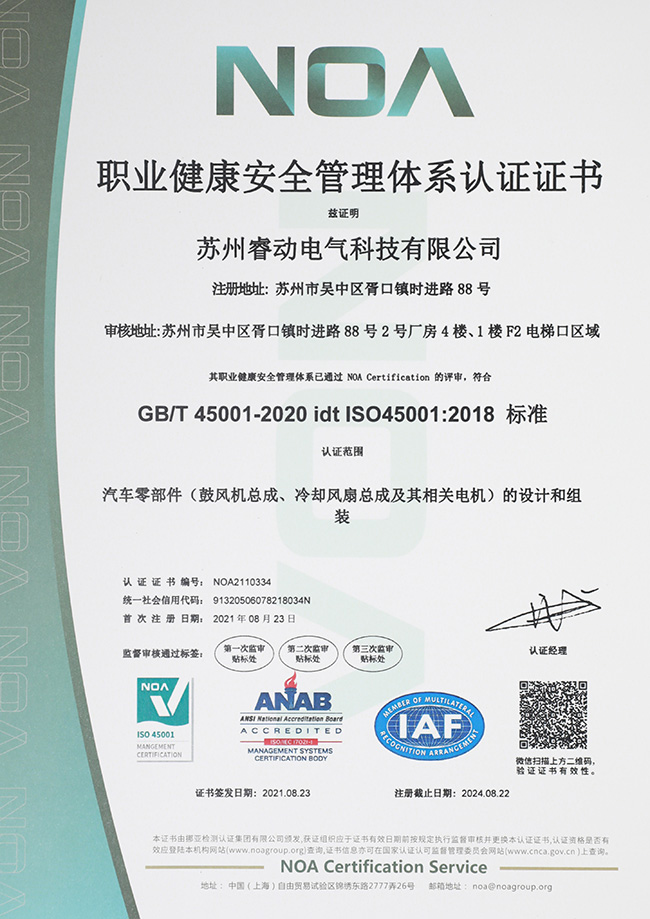

Quality System

-

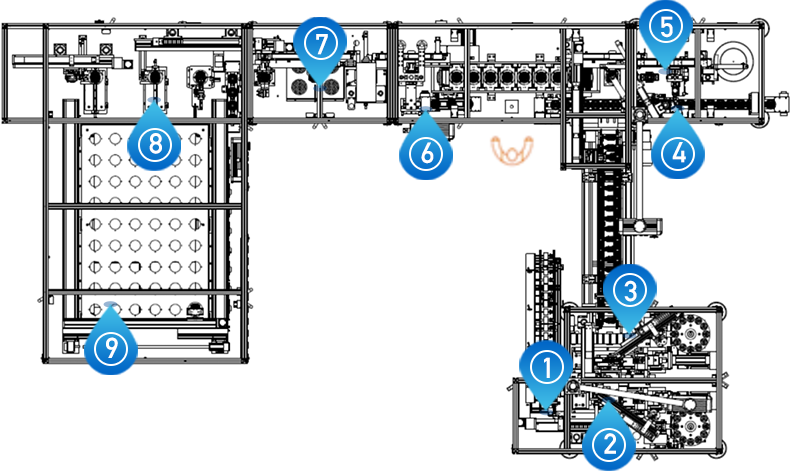

Iron core into the shaft

Shaft press-in length error proofing, shaft-into iron core pressure monitoring, commutator-into-shaft pressure monitoring

-

Slot insulation paper

Ensure the length of insulating paper through cam mechanism, and detect the sensor to prevent missed insertion and inappropriate insertion.

-

Winding

100% monitoring of the wire length of the winding machine to prevent the left and right groups of the rotor from exceeding the specified standard.

-

Spot welding

The spot welding machine adopts Miyaki welding to reduce the thermal conduction to the commutation piece

-

Performance test

Automatic identify the defective rotor performance to prevent the defective products from deliver to the next process

-

Grinding

After the bearing gear is cleaned, it is necessary to ensure that the base surface of the finished vehicle is clean and tidy, so as to ensure the quality of the fine turning.

-

Refine the vehicle

Turn the cutting tool forward and backward to ensure that the slot of the commutator is free of burrs, and number of brushes of the turning tool is controlled

-

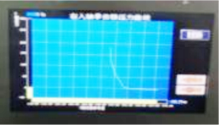

Dynamic balance

The first domestic armature balance When it is NG,the stopper will block the part from being removed

It prevents damage to the equipment after the rotor is reversed manually

-

100% monitoring of bearing press-in force

-

Automatic sorting and isolation when the bearing pressing force is unqualified

-

Automatically adjust the assembly angle of the stator to ensure the consistent assembly angle

-

It prevents the wave washers from missing and multi-installed

-

Automatic sorting and isolation after the axial clearance is unqualified

-

It prevents the motor magnetization from being unsaturated due to incorrect charging angle

-

Prevent the motor with jamming and poor grounding from delivering the next process

-

It prevents the motor from starting the running-in command, but actually the motor does not rotate due to poor power supply

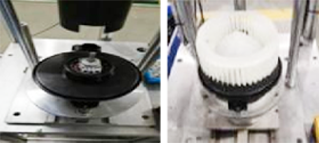

Motor tooling positioning and flange locating pin error proofing. Press the impeller behind the top motor shaft to prevent the impeller from being damaged by external force

-

Unqualified dynamic balance of fan cannot be taken out, it cannot be taken out until the balance is qualified, so as to prevent the fan from shaking badly

-

100% full inspection of fan performance, and automatic alarm for unqualified equipment

-

In the HVAC, the fan listens to the comfort according to each gear of the actual vehicle